Resin dispensing technology

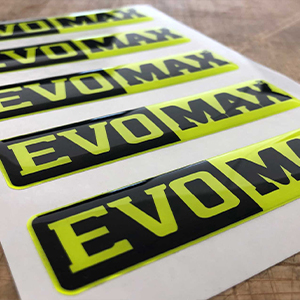

Resin dispensing technology This type of processing aims to provide a high-quality product that can meet the demands of the most demanding customers. Seritarghe has invested in numerically controlled machines, able to follow the most complex resin profiles, as well as to automatically manage the degassification of resin, catalyst and automated dose in environments with humidity and temperature controlled. We are able to resine on any type of PVC support, giving shine and a three-dimensional prominence to the stickers we printed (or screen-printed) and dieboard. Particular attention is given to the purchase of the raw material: the resins, all of which are RoHS certified (free of heavy metals). In recent years, thanks to the performance of the machinery and the continuous research, we have developed and are now able to residify on profiles of LED bars; This processing is achievable with either the traditional resin, the hard glass effect resin, or the opal resin.