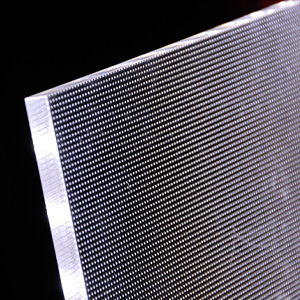

Blacklight panels

Blacklight panels Thanks to continuous investments, Seritarghe is able to create plexiglass panels with BACKLIGHT technology, the line of LED backlight panels is fully customizable, both in terms of shapes, dimensions, thicknesses and points of light emission. Thanks to laser technology and an algorithm which, depending on the position of the light source, calculates the optimal light diffusion pattern (dots or dashes) and generates micro-incisions also known as LGP (Light Guide Panel), ideal for creating medium-sized illuminated surfaces and large size. The light of the BACKLIGHT panels manages to illuminate uniformly and without a shaded area.

Laser labelling

Laser labelling Laser labeling consists in chemically modifying a support, through the use of a laser ray; the support thus become indelibly black. This process is used more and more because it is very quick and versatile, and thus competitive on the costs for big and small productions. With labeling is possible to obtain progressive numerations, barcodes, QRcodes, and materials traceability.

Decorations

Decorations Seritarghe realizes stickers and decorations for both industial machinery of shops. We can work from a design provided by the client or created by our experienced design office.

Signs and advertising banners

Signs and advertising banners Seritarghe realizes advertsing signs for indoors/outdoors, one-sided or two-sided print for both adhesive or non adhesive support, for outdoors in vynil resistant cloth/polycarbonate. We also offer different kinds of finishing, as eyelet, buttonhole and support.

Advertising signs

Signboards Seritarghe realizes signboards, either traditional, led or neon lit in various sizes. We can work from a design provided by the client or created by our experienced design office.

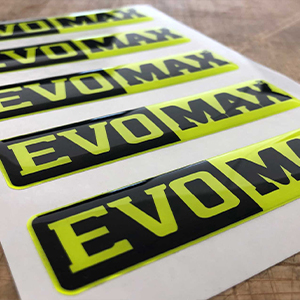

Resin dispensing technology

Resin dispensing technology This type of processing aims to provide a high-quality product that can meet the demands of the most demanding customers. Seritarghe has invested in numerically controlled machines, able to follow the most complex resin profiles, as well as to automatically manage the degassification of resin, catalyst and automated dose in environments with humidity and temperature controlled. We are able to resine on any type of PVC support, giving shine and a three-dimensional prominence to the stickers we printed (or screen-printed) and dieboard. Particular attention is given to the purchase of the raw material: the resins, all of which are RoHS certified (free of heavy metals). In recent years, thanks to the performance of the machinery and the continuous research, we have developed and are now able to residify on profiles of LED bars; This processing is achievable with either the traditional resin, the hard glass effect resin, or the opal resin.

Mechanical working

Mechanical workings Our company is equipped with punches, benders, shears and every other machinery necessary to the preparation, production and assembly of elements for light metal structures. Some examples of product we realize:

Plastic materials processing

Plastic material processing Products on design Seritarghe realizes details on design, done with CNC machineries on technical plastics materials as: Cut We perform cut of plastic materials of any size and geometric shape; according to the material we use pantograph circular hacksaw laser technologies or shears.Bending According with the kind of materials we perform bending with cold bender, hot bender or 45° mill.